The LS transmission manual is a comprehensive guide for understanding and maintaining the LS transmission system. It provides detailed insights into operation, maintenance, and troubleshooting, ensuring optimal performance and longevity. This manual is essential for drivers and mechanics to maximize efficiency and address common issues effectively;

1.1 Overview of the LS Transmission

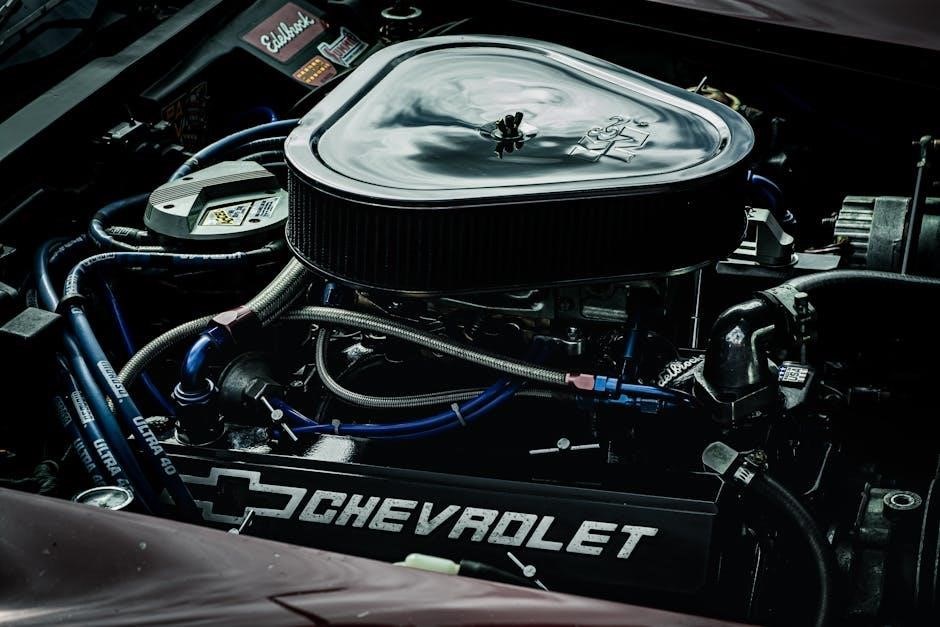

The LS transmission is a widely recognized manual transmission system known for its durability and smooth performance. Designed to handle high torque and speed, it is often used in performance vehicles. The LS transmission features a robust gear setup and clutch operation, making it popular among driving enthusiasts. Its compact design and versatility allow it to be used in various vehicle applications, from everyday driving to racing. This transmission is prized for its reliability and responsiveness, ensuring a seamless driving experience across different conditions and driving styles.

1.2 Importance of the Manual in Vehicle Maintenance

The LS transmission manual is a vital resource for proper vehicle maintenance, providing detailed instructions for troubleshooting and preventing issues. It helps drivers and mechanics understand the transmission’s operation, enabling early detection of potential problems. Regular maintenance, as outlined in the manual, can prevent costly repairs and ensure optimal performance. By following the manual’s guidelines, users can extend the lifespan of their transmission and enhance driving efficiency. This resource is essential for anyone looking to maintain or repair their LS transmission effectively.

Components of the LS Transmission

The LS transmission comprises essential components like gears, bearings, clutch packs, and the torque converter. Transmission fluid lubricates these parts, ensuring smooth operation and longevity.

2.1 Key Parts and Their Functions

The LS transmission consists of critical components designed for seamless operation. Gears transmit power between the engine and wheels, while bearings support moving parts to reduce friction. The torque converter regulates torque transfer, ensuring smooth acceleration. Clutch packs engage and disengage gears, enabling precise shifting. Seals and gaskets prevent fluid leaks, maintaining hydraulic pressure. Sensors monitor speed and pressure, providing data for optimal shifting. Each part works harmoniously to ensure efficient power delivery, reliability, and driver control. Understanding these components is vital for proper maintenance and troubleshooting.

2.2 Transmission Fluid and Its Role

Transmission fluid is essential for lubricating gears, cooling components, and enabling smooth hydraulic operation. It ensures proper clutch engagement and prevents wear on moving parts. Regular fluid changes, typically every 30,000 to 60,000 miles, are crucial for maintaining performance and preventing damage. The fluid also acts as a hydraulic medium, facilitating gear shifts and torque transfer. Using the correct type of transmission fluid, as specified in the LS manual, is vital for optimal functionality and longevity of the transmission system.

Maintenance and Service Intervals

Regular maintenance ensures the LS transmission operates efficiently. Fluid changes every 30,000 to 60,000 miles, along with filter replacements, are critical for optimal performance and longevity.

3.1 Recommended Service Schedule

The LS transmission manual outlines a detailed service schedule to ensure optimal performance. Fluid changes are recommended every 30,000 to 60,000 miles, depending on driving conditions. Filters should be replaced every 15,000 to 30,000 miles to maintain cleanliness and flow. Inspecting the driveshaft and axles annually is crucial to prevent vibration issues. Transmission mounts should be checked every 30,000 miles for wear. Additionally, clutch systems require inspection every 15,000 miles to ensure proper engagement and disengagement. Following this schedule helps prevent premature wear and ensures smooth operation, extending the transmission’s lifespan.

3.2 Signs of Wear and Tear

Identifying wear and tear in the LS transmission is crucial for early intervention. Common signs include slipping or hesitation between gears, unusual noises during shifting, and leaks around the transmission pan. Drivers may notice a delay in acceleration or a “grinding” sensation when changing gears. Additionally, a burning smell or discolored transmission fluid indicates overheating or internal damage. Vibrations felt through the clutch pedal or steering wheel can signal worn bearings or misaligned components. Addressing these signs promptly prevents minor issues from escalating into costly repairs.

Troubleshooting Common Issues

Troubleshooting the LS transmission involves identifying and addressing common problems like slipping gears or difficulty shifting. Check fluid levels, inspect for leaks, and ensure proper clutch engagement.

4.1 Diagnosing Slipping Gears

Diagnosing slipping gears in the LS transmission involves identifying abnormal performance during acceleration or shifting. Common signs include hesitation, unusual noises, or the transmission disengaging under load. Check the transmission fluid level and condition, as low or degraded fluid can cause slipping. Inspect for leaks, worn clutch packs, or faulty solenoids. Use a scan tool to retrieve trouble codes, which can pinpoint issues like pressure sensor malfunctions or torque converter problems. A thorough inspection of the gearset and bearings may also be necessary to identify mechanical failures.

4.2 Addressing Difficulty in Shifting

Difficulty in shifting gears in the LS transmission can stem from various issues, including worn synchronizers, faulty shift sensors, or improper clutch engagement. Check the transmission fluid level and consistency, as insufficient or degraded fluid can impede smooth shifting. Inspect the shift linkage and cables for damage or misalignment. If problems persist, scan for trouble codes using a diagnostic tool to identify sensor or solenoid malfunctions. In some cases, replacing worn components or recalibrating the transmission control module (TCM) may be necessary to restore smooth operation. Professional assistance is recommended for complex repairs.

Repair and Replacement Options

The LS transmission offers various repair options, from DIY fixes for minor issues to professional overhauls. Replacing damaged components like clutches or bearings can restore functionality. Professional expertise is often required for complex rebuilds or fluid system repairs to ensure reliability and performance.

5.1 DIY Fixes for Minor Problems

DIY fixes for minor LS transmission issues can save time and money. Common problems like low transmission fluid levels or dirty filters can often be resolved with basic tools. Replacing the filter or topping up fluid are straightforward tasks. For slight leaks, inspecting and tightening connections may suffice. However, it’s crucial to follow the manual’s guidelines to avoid further damage. Simple adjustments, like cleaning the transmission pan or replacing worn gaskets, can prevent major repairs. Always ensure the vehicle is on level ground and consult the manual before starting any DIY repair.

5.2 When to Seek Professional Help

While minor issues can be addressed with DIY fixes, certain problems require professional expertise. If you notice symptoms like slipping gears, unusual noises, or persistent leaks, it’s best to consult a specialist. Major repairs, such as rebuilding the transmission or replacing internal components, demand advanced tools and knowledge. DIY attempts in these cases can lead to further damage or safety risks. Always seek help from a qualified mechanic if you’re unsure about the severity of the issue or lack the necessary skills and equipment to resolve it effectively.

Driving Techniques for Manual Transmissions

Mastering driving techniques for manual transmissions enhances control and efficiency. Smooth shifting and clutch control are crucial for optimal performance, fuel efficiency, and minimizing wear on components.

6.1 Mastering Smooth Shifting

Mastering smooth shifting in a manual transmission requires precise coordination between the clutch and accelerator. Start by pressing the clutch fully and shifting into first gear. As you release the clutch, gently press the accelerator to avoid jerking. When shifting into higher gears, use the shift indicator to guide timing and feel for the clutch’s “bite point.” Practice in a safe, open area to develop muscle memory and ensure seamless transitions. Smooth shifting reduces wear on components and enhances the driving experience, making it essential for both new and experienced drivers.

6.2 Clutch Control and Best Practices

Proper clutch control is essential for smooth driving and extending the life of your LS transmission. Always press the clutch fully before shifting gears to avoid grinding or wear. Use the “bite point” technique—releasing the clutch gradually until you feel resistance—to ensure smooth starts. Avoid “riding the clutch,” as this can cause unnecessary wear. When stopping on an incline, use the handbrake and downshift before coming to a full stop. Regularly check and adjust the clutch pedal’s free play to maintain optimal performance and prevent premature failure. These practices enhance control and reduce long-term maintenance costs.

The Future of Manual Transmissions

Manual transmissions are evolving with advancements in technology, offering better fuel efficiency and performance. Despite automatics’ popularity, enthusiasts continue to embrace manuals for their control and driving experience;

7.1 Evolution of Manual Transmissions

Manual transmissions have undergone significant advancements over the years, from mechanical to hydraulic and electronic systems. Modern manuals now feature lightweight materials, improved synchronization, and better gear ratios for enhanced performance. The integration of technology, such as rev-matching and automated manual transmissions, has bridged the gap between manual and automatic systems. These innovations cater to both performance enthusiasts and everyday drivers, ensuring manuals remain relevant in an era dominated by automatics. The focus on fuel efficiency and driver engagement continues to shape the future of manual transmissions;

7.2 Popularity in Modern Vehicles

Manual transmissions remain popular in modern vehicles, especially among driving enthusiasts who value control and engagement. While automatics dominate the market, manuals are still favored in sports cars, performance vehicles, and some trucks. Their appeal lies in the direct connection to the vehicle and fuel efficiency. Modern manuals often feature advanced tech like rev-matching and lightweight designs. Despite the rise of automatics, manuals maintain a niche appeal, offering a unique driving experience that many drivers prefer. This enduring popularity ensures manual transmissions continue to be relevant in contemporary automotive design.